The Essential Role of Parts Lathe Machines in Modern Metal Fabrication

In the ever-evolving landscape of manufacturing, parts lathe machines stand out as crucial tools that enhance productivity, precision, and innovation. These machines, often considered the backbone of metal fabrication, play a significant role in various industries, from automotive to aerospace. This comprehensive guide delves into the nuances of parts lathe machines, their functionalities, types, and their undeniable impact on modern manufacturing.

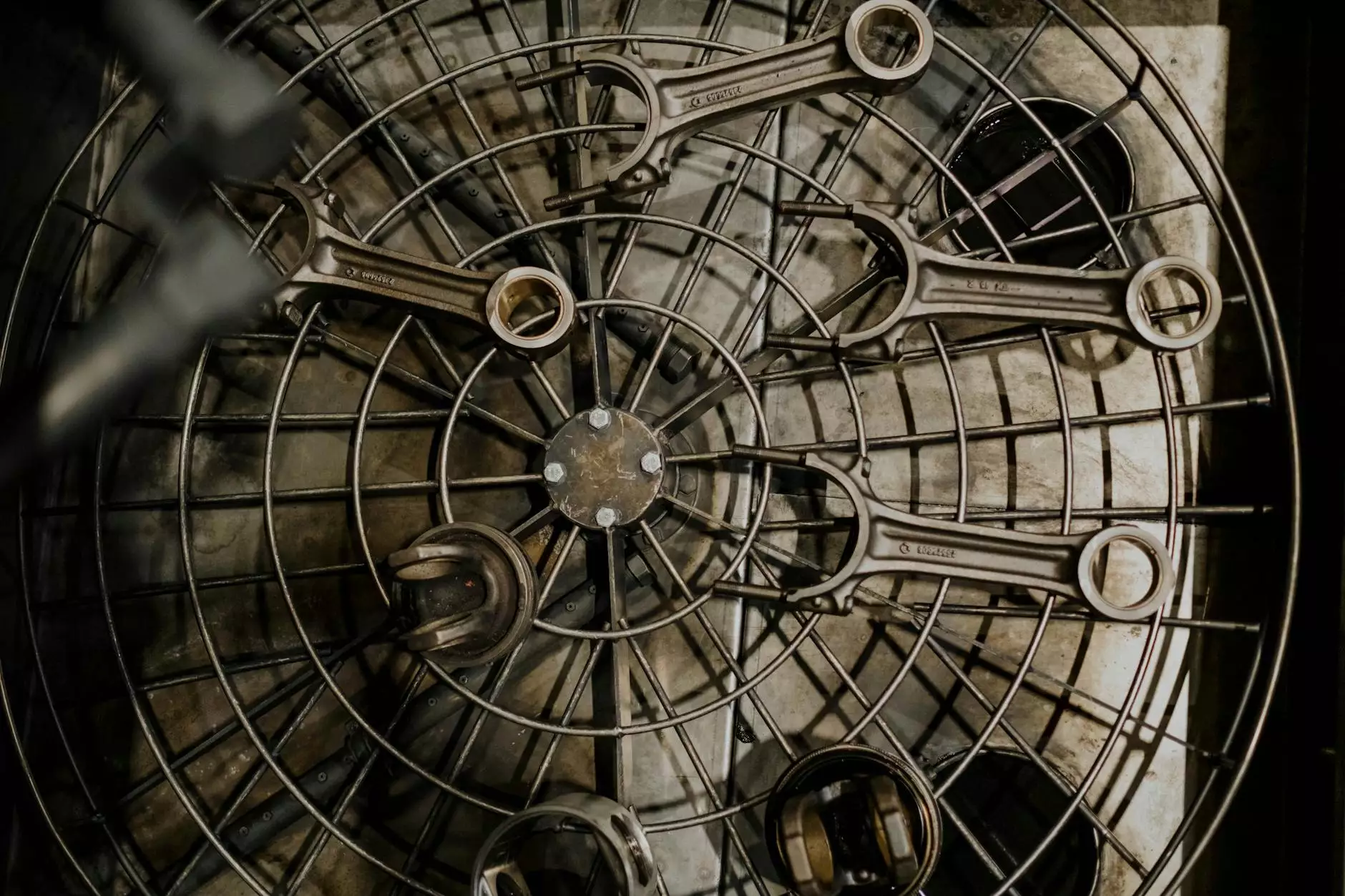

What Is a Parts Lathe Machine?

A parts lathe machine, commonly known simply as a lathe, is a versatile tool designed for shaping materials, typically metals, by removing material from a rotating workpiece. The fundamental operation involves spinning the workpiece on a spindle while a cutting tool is precisely moved along the workpiece to achieve the desired shape and dimensions. This process is known as turning, and it allows for the creation of cylindrical, conical, or complex geometric shapes.

Applications of Parts Lathe Machines

The applications of parts lathe machines are vast and varied. Below are some key sectors that rely heavily on these machines for production and manufacturing processes:

- Automotive Industry: Used for producing components such as shafts, spindles, and other precision parts.

- Aerospace Sector: Essential for crafting high-precision parts that meet stringent safety and performance standards.

- Medical Device Manufacturing: Employed to produce intricate components required for surgical instruments and devices.

- Machinery and Equipment: Vital in creating parts for various machinery, ensuring reliable operation and maintenance.

- Custom Fabrication: Popular among fabricators for one-off pieces or prototypes tailored to specific client needs.

Types of Parts Lathe Machines

Understanding the different types of lathe machines can greatly enhance your knowledge of their function and application in various settings. Here are some common types of parts lathe machines:

1. Engine Lathes

Engine lathes are among the most traditional types and are ideal for general-purpose work. They are versatile, allowing for different types of operations including turning, drilling, and boring.

2. CNC Lathes

Computer Numerical Control (CNC) lathes automate the turning process, offering enhanced precision and efficiency. These machines are programmed with CAD models, allowing for complex designs to be executed with minimal human intervention.

3. Turret Lathes

Turret lathes incorporate a rotating turret that holds multiple cutting tools. This configuration saves time when multiple operations are needed, as tools can be changed quickly without manual adjustment.

4. Swiss Lathes

Swiss lathes are designed for machining small and intricate parts with high precision. Their unique mechanism allows for the workpiece to be held securely while multiple tools work simultaneously.

5. Vertical Lathes

Vertical lathes, or vertical turning machines, are used primarily for large components and have the workpiece oriented vertically. They provide stability and support for heavy workpieces, enhancing safety and precision.

Advantages of Using Parts Lathe Machines

The integration of parts lathe machines into manufacturing processes comes with numerous benefits that contribute to operational efficiency and product quality. Here are some advantages to consider:

- Precision and Accuracy: The principal advantage of lathe machines is their ability to produce high-precision components with exceptional tolerances, ensuring that parts fit together perfectly.

- Versatility: Parts lathe machines can handle a wide range of materials and can be used to manufacture various shapes, increasing their utility in metal fabrication.

- Increased Production Speed: Especially with CNC lathes, production cycles are shortened dramatically, allowing businesses to meet high demand efficiently.

- Automation: Advanced lathes feature automation, which reduces the need for manual labor and minimizes human error, further enhancing production quality.

- Cost-Effectiveness: By improving the manufacturing process and reducing waste, parts lathe machines contribute to lowering operational costs.

Choosing the Right Parts Lathe Machine for Your Business

Selecting the correct parts lathe machine requires careful consideration of several factors. Here are key elements to evaluate:

1. Type of Workpiece

Consider the size, shape, and material of the components you will be machining. Different lathes are suited for different types of workpieces.

2. Production Volume

For high production volumes, CNC lathes might be the most effective choice due to their speed and automation capabilities. For lower volume, custom work, traditional engine lathes may suffice.

3. Precision Requirements

Your precision requirements will dictate the type of lathe you need. Closer tolerances may necessitate advanced CNC or Swiss lathes.

4. Budget Considerations

Evaluate your budget against the cost of different machines and their operational expenses, factoring in maintenance, tooling, and the potential return on investment.

Maintaining Your Parts Lathe Machine

Regular maintenance of parts lathe machines is essential to ensure longevity and performance. Implementing a scheduled maintenance plan can prevent unexpected breakdowns and enhance productivity. Here are some maintenance tips:

- Regular Inspection: Perform routine checks to identify wear and tear early.

- Cleaning: Keeping the machine clean from chips and residue will prevent malfunctions.

- Lubrication: Regularly lubricate moving parts to minimize friction and wear.

- Calibration: Schedule periodic calibrations to ensure the lathe maintains the required precision.

- Tool Replacement: Monitor and replace cutting tools as necessary to maintain cutting quality.

Conclusion

The importance of parts lathe machines in the realm of metal fabrication cannot be overemphasized. Their ability to produce complex, high-precision components rapidly and cost-effectively makes them indispensable in contemporary manufacturing environments. Businesses like Deep Mould benefit greatly from integrating advanced lathe technology into their operations, allowing them to stay competitive in today's fast-paced market.

As industries gear up for continuous advancement, investing in the right lathe machines and ensuring proper maintenance will equip businesses to meet future challenges. Whether you are involved in automotive, aerospace, or custom fabrication, understanding and leveraging the potential of parts lathe machines will drive success and innovation in your operations.