Maximizing Efficiency with Label Applicators in Your Business

In today's fast-paced business environment, efficiency and accuracy are paramount. Companies across various sectors, including printing services, electronics, and computers, strive to streamline their processes to enhance productivity and reduce costs. One of the most effective tools to achieve this is the label applicator. This article delves deep into the world of label applicators, uncovering their benefits, types, usage, and how they can significantly enhance your business operations.

What is a Label Applicator?

A label applicator is a machine designed to automate the process of applying labels to products or packaging. These machines can handle various types of labels and materials, ensuring that they are applied accurately and consistently, which is essential for maintaining brand integrity and compliance with industry standards.

Why Use Label Applicators?

Integrating a label applicator into your operations can yield numerous benefits, including:

- Increased Efficiency: Automating the labeling process allows for a significant increase in speed, enabling businesses to process more products in less time.

- Consistency and Accuracy: Label applicators provide uniform application of labels, reducing human errors and ensuring compliance with regulations.

- Cost-Effective: While there is an upfront cost to purchasing label applicators, the long-term savings in labor costs and waste reduction make them a wise investment.

- Flexibility: Many label applicators are adjustable and capable of handling various label sizes, shapes, and materials, making them highly versatile.

- Improved Aesthetics: Professional looking labels enhance the appeal of products, contributing to better sales potential.

Types of Label Applicators

Understanding the different types of label applicators available can help you choose the right one for your business needs. Here are some common types:

1. Manual Label Applicators

These require human intervention to apply labels. They are often used in smaller operations where flexibility is key and production volumes are lower.

2. Semi-Automatic Label Applicators

These machines require some manual input but automate significant portions of the labeling process. They are ideal for medium-sized businesses that require higher output without investing in fully automated systems.

3. Fully Automatic Label Applicators

Designed for high-volume production environments, these applicators can automatically feed, position, and apply labels, drastically increasing efficiency.

4. Print and Apply Labeling Systems

This type combines printing and application into a single machine, allowing businesses to print variable information on labels right before application. This is particularly useful for industries that require dynamic labeling, such as food and beverage or pharmaceuticals.

Applications of Label Applicators

Label applicators find usage across diverse sectors due to their versatility. Here are some key applications:

1. Food and Beverage

In the food industry, accurate labeling is crucial for compliance with health regulations and providing essential product information to consumers. Label applicators ensure labels are applied consistently and accurately on various packaging types.

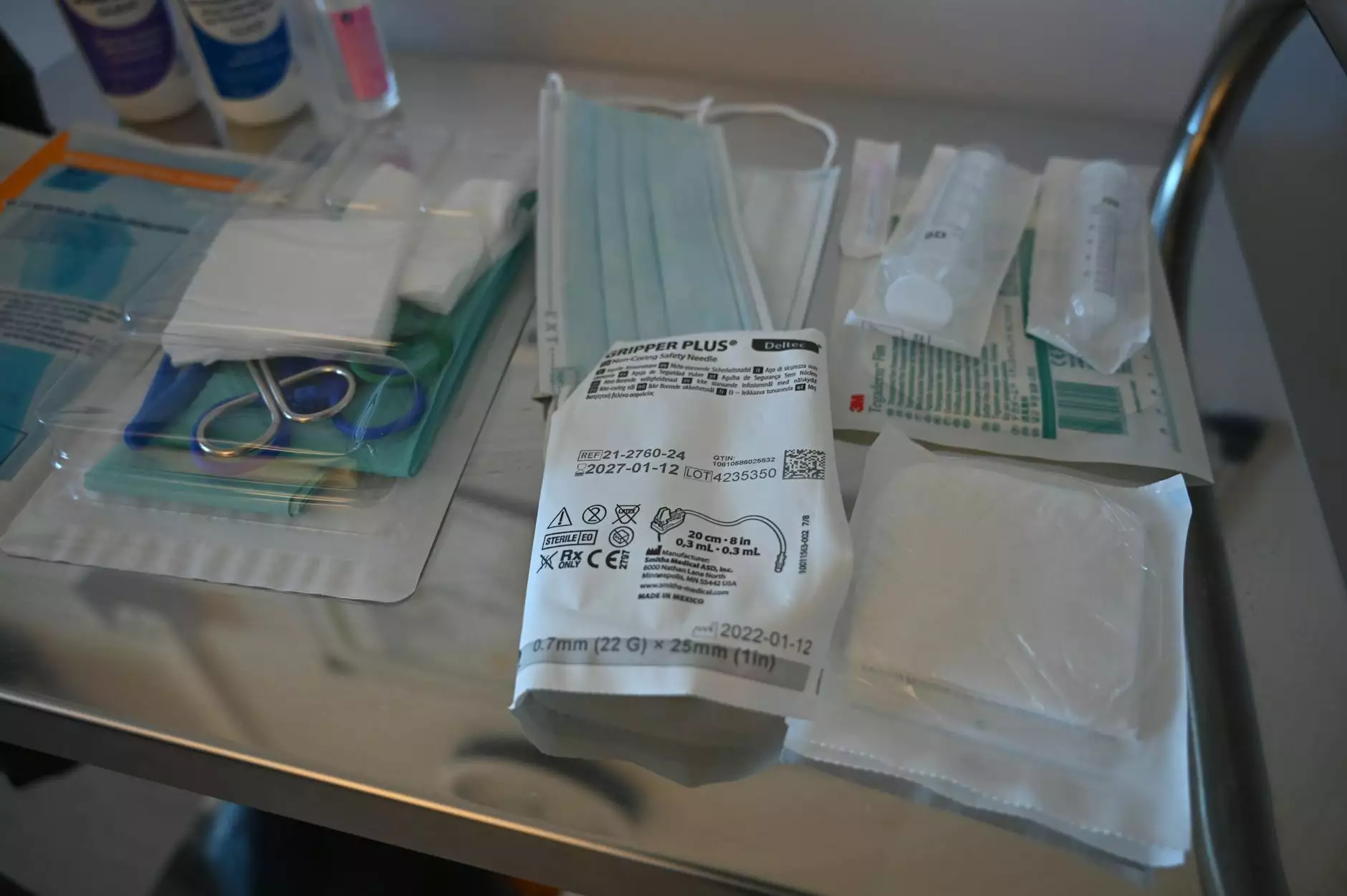

2. Pharmaceuticals

In pharmaceuticals, labels often contain critical information regarding dosages, ingredients, and expiration dates. Automating this process with a label applicator minimizes risk and enhances safety.

3. E-commerce

As e-commerce continues to grow, businesses need efficient labeling solutions for shipping packages. Label applicators speed up the process, ensuring that packages are shipped quickly and accurately.

4. Manufacturing

In manufacturing environments, labels are often applied to products for identification, branding, and tracking purposes. Automated solutions help streamline production lines.

Choosing the Right Label Applicator for Your Business

Selecting the right label applicator involves considering several factors:

- Production Volume: Determine how quickly you need labels applied and choose an applicator that meets those needs.

- Type of Product: Consider the surfaces and structures of the products being labeled. Some applicators handle curved surfaces better than others.

- Label Specifications: Ensure that the applicator can accommodate the size, shape, and material of the labels you use.

- Space and Layout: Evaluate the physical space where the applicator will be used. Some require more space than others.

- Integration with Existing Systems: Consider how well the applicator will integrate with your current production or packaging lines.

Maintenance of Label Applicators

To ensure longevity and optimal performance, regular maintenance of label applicators is essential:

- Routine Cleaning: Dust and label residue can accumulate, so cleaning the applicator regularly helps maintain its function.

- Inspecting Mechanical Components: Regularly check parts such as rollers and motors for wear and tear.

- Alignments: Ensure that the label applicator is properly aligned to prevent mislabeling.

- Software Updates: If your applicator includes software controls, make sure it’s up to date for optimal performance.

Case Studies: Success with Label Applicators

1. ABC Foods

ABC Foods, a mid-sized food manufacturer, integrated a fully automatic label applicator into their production line. This investment allowed them to increase their output by 30% while reducing labeling errors by 70%. The improved efficiency made it possible for them to accept additional orders without sacrificing quality.

2. XYZ Pharmaceuticals

XYZ Pharmaceuticals faced challenges in keeping up with regulatory demands for accurate labeling. By introducing print and apply systems, they not only maintained compliance but also won back customer trust, leading to a 25% increase in sales.

The Future of Label Applicators

The advancement in technology suggests exciting possibilities for the future of label applicators. Innovations in AI and machine learning may lead to smarter systems capable of adapting to different products on-the-fly, significantly enhancing productivity even further.

Conclusion

Incorporating a label applicator into your business processes can provide substantial advantages. From improving efficiency and accuracy to enhancing compliance and customer satisfaction, these devices are invaluable assets in the modern business landscape. As companies like Omega Brand continue to innovate, the potential for label applicators to transform labeling processes remains vast. Investing in the right label applicator will not only elevate your operations but also help you stay competitive in a rapidly evolving market.