Plastic Rapid Prototypes Suppliers: Elevating Your Business with Innovation

In the rapidly evolving landscape of manufacturing, having a reliable source of plastic rapid prototypes suppliers is essential for businesses looking to stay ahead of the competition. This article delves deep into the world of rapid prototyping, exploring its significance, processes, and how partnering with the right suppliers can transform your product development strategy.

What is Plastic Rapid Prototyping?

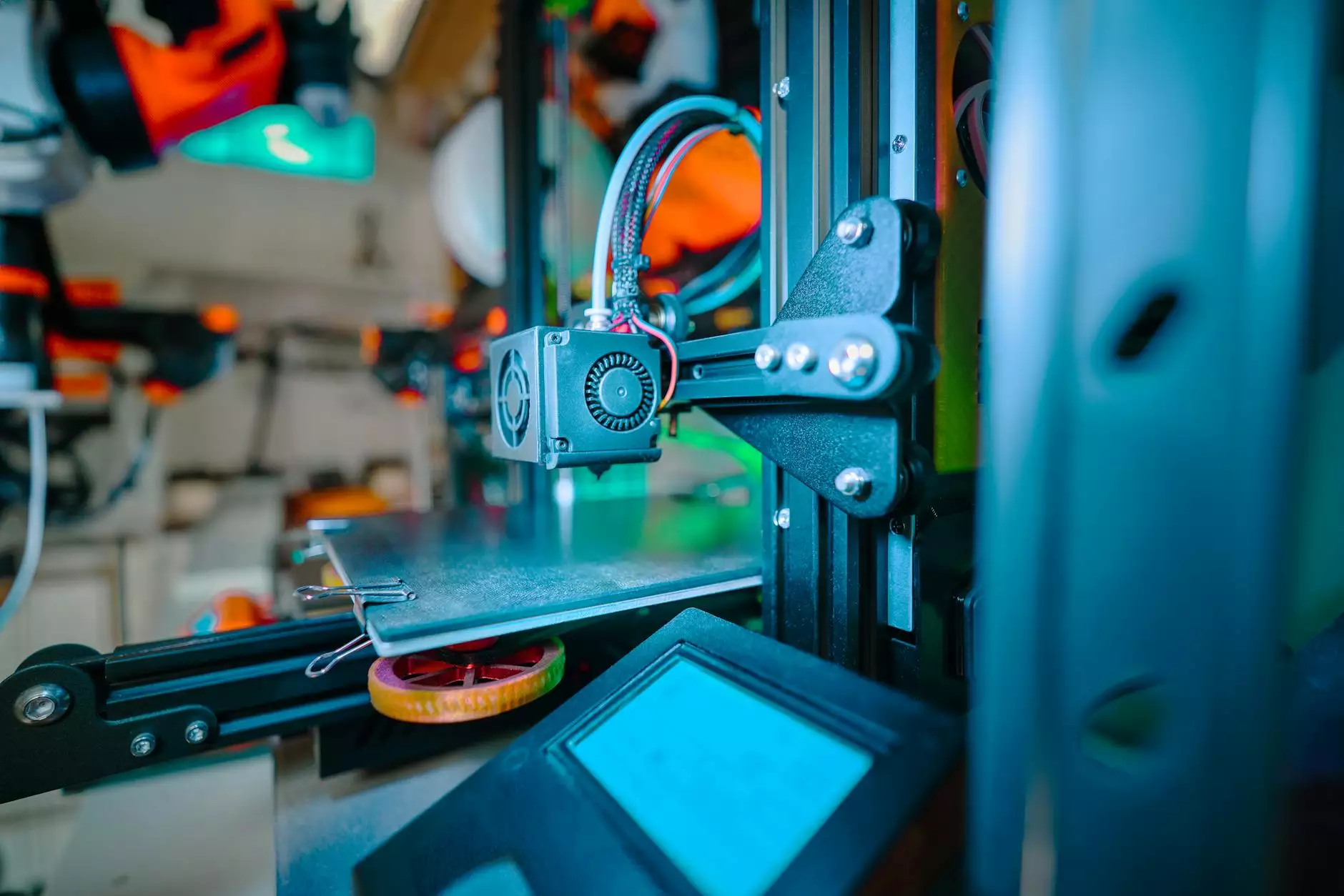

Plastic rapid prototyping is an advanced manufacturing technique that allows businesses to quickly create prototypes of their product designs using plastic materials. This process enables designers and engineers to visualize, test, and refine their concepts before moving into full-scale production.

Key Advantages of Rapid Prototyping

- Speed: Rapid prototyping accelerates the product development cycle. Products can be designed, built, and tested in significantly shorter time frames compared to traditional methods.

- Cost-Effective: By identifying design flaws early in the process, companies can avoid costly changes during full-scale production.

- Improved Accuracy: Advanced CAD (Computer-Aided Design) and 3D printing technologies ensure high fidelity in reproducing designs.

- Flexibility: Rapid prototyping allows for modifications and iterations to be made on the fly, enabling a more agile product development process.

The Role of Plastic Rapid Prototypes Suppliers

Choosing the right plastic rapid prototypes suppliers can make all the difference in the success of a project. Suppliers are not just vendors; they are partners who can provide expertise, resources, and innovative solutions tailored to your specific needs.

Evaluating Your Requirements

Before selecting a supplier, it’s crucial to clearly define your requirements. Consider the following factors:

- Material Specifications: The type of plastic used can impact the functionality, durability, and appearance of the prototype.

- Production Volume: Understand whether you'll need single prototypes or multiple iterations, as different suppliers may specialize in various scales of production.

- Technology Used: Suppliers may utilize different methods such as SLA (Stereolithography), SLS (Selective Laser Sintering), or FDM (Fused Deposition Modeling). Each technique has unique characteristics and advantages.

- Turnaround Time: Ensure that the supplier can meet your deadlines without compromising on quality.

Types of Plastic Used in Rapid Prototyping

A myriad of plastics can be employed in rapid prototyping, each offering varied properties. Here are some commonly used materials:

- ABS (Acrylonitrile Butadiene Styrene): Known for its strength, flexibility, and resistance to impact, ABS is a common choice for functional prototypes.

- PLA (Polylactic Acid): A biodegradable thermoplastic derived from renewable resources, PLA is ideal for projects that require environmentally friendly materials.

- Nylon: Renowned for its durability and flexibility, nylon is perfect for prototypes that require a higher degree of resilience.

- Polycarbonate: This material offers excellent optical clarity and impact resistance, making it suitable for prototypes that need to be both aesthetic and functional.

Steps in the Rapid Prototyping Process

The journey from concept to prototype involves several key stages:

1. Conceptualization

This initial stage involves brainstorming ideas and creating rough sketches of the product design. Collaboration with your plastic rapid prototypes suppliers at this stage can bring valuable insights regarding feasibility and materials.

2. Design Development

Using CAD software, the design is digitized, allowing for precision and intricate detailing. At this point, it’s essential to engage your suppliers for feedback on design aspects that may affect manufacturing.

3. Prototype Fabrication

Once the design is finalized, the prototype is fabricated using the chosen rapid prototyping technique. This may involve 3D printing or injection molding, depending on the requirements.

4. Testing and Iteration

The prototype undergoes rigorous testing to evaluate its functionality and identify areas for improvement. Iterations may be necessary, and suppliers play a key role in making these modifications efficiently.

5. Finalization

After thorough testing and refinement, the final prototype can be approved for mass production. A trusted supplier will ensure seamless transition into full-scale manufacturing.

How to Choose the Right Supplier

Selecting the correct plastic rapid prototypes suppliers involves a delicate balance of various factors:

- Industry Experience: Opt for suppliers who have a proven track record in your industry. Their understanding of market specifics can add value to your project.

- Portfolio Review: Examine previous projects to assess the supplier’s capability in delivering quality prototypes.

- Customer Service: Timely communication and support are crucial. Choose suppliers who offer dedicated client service throughout the prototyping process.

- Scalability: Opt for suppliers that can grow with your business. If your project expands, will they be able to meet increased production needs?

The Future of Plastic Rapid Prototyping

As technology progresses, the future of plastic rapid prototypes suppliers looks promising. Advancements in materials science and manufacturing processes are paving the way for:

- Increased Customization: Suppliers will be able to offer a wider variety of materials customized to specific application needs.

- Sustainability: The rise of eco-friendly materials will allow businesses to reduce their environmental impact while maintaining product quality.

- Automation and Artificial Intelligence: The integration of AI in design and production processes promises greater efficiency and reduced lead times.

Conclusion

In conclusion, the collaboration with plastic rapid prototypes suppliers is a pivotal factor in enhancing the product development cycle for any business. By leveraging the advantages of rapid prototyping and maintaining a strategic partnership with skilled suppliers, companies can significantly reduce costs, ensure design accuracy, and accelerate time-to-market.

Investing in quality rapid prototyping not only improves your product outcomes but also enhances your competitive edge in the marketplace. As you embark on this journey, remember that the right supplier is your best ally in navigating the nuances of manufacturing innovation.

For businesses ready to elevate their design and manufacturing processes, consider reaching out to reputable suppliers like DeepMould.net, who can provide the expertise and resources necessary to turn your ideas into reality.